Solutions agricoles

Solutions médicales

Celitron développe et fabrique des stérilisateurs à vapeur d’eau (autoclaves) pour le contrôle des infections dans les cabinets dentaires, les cliniques et les hôpitaux, ainsi que des solutions pour le traitement des déchets de soins à risques infectieux pour les hôpitaux.

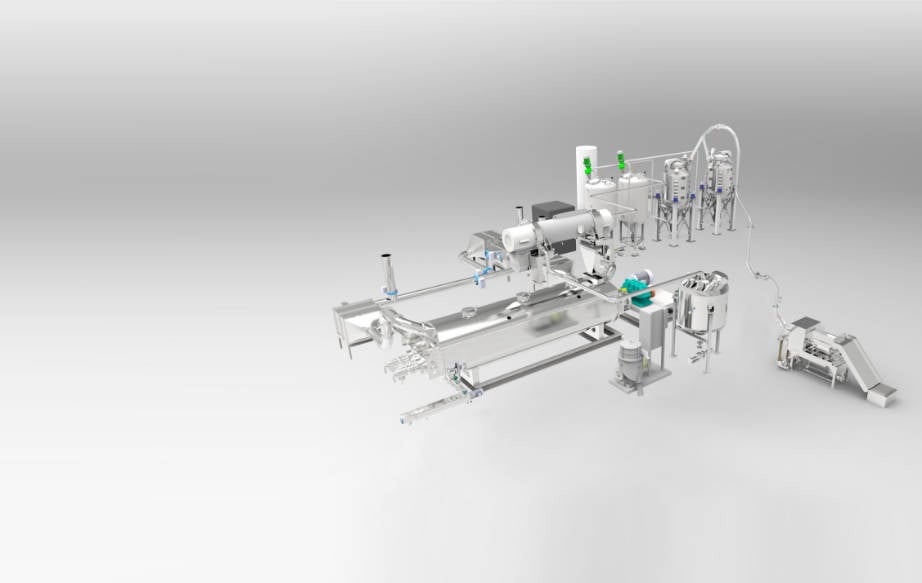

Nous avons aussi des solutions pour l’industrie agricole. Notre installation ISS AGRI a été développée pour recycler les sous-produits animaux et extraire les protéines et les huiles d’insectes.

À propos de nous

Notre présence est internationale avec plus de 500 unités de traitement des déchets médicaux et plus de 5000 stérilisateurs à vapeur d’eau répartis dans plus de 80 pays à travers le monde.

Notre technologie brevetée ayant été développée à partir des principes de stérilisation, toutes nos machines sont par conséquent basées sur la stérilisation médicale.

Notre unité de traitement des déchets médicaux, qui constitue une solution écologique pour l’élimination des déchets de soins à risques infectieux, a été développée en fonction des besoins du marché.