Celitron workshop secrets: The steam generator plays a key role in AC series sterilizers

25-04-2025

Celitron Workshop Secrets. How is the Steam Generator Made and How Does It Work?

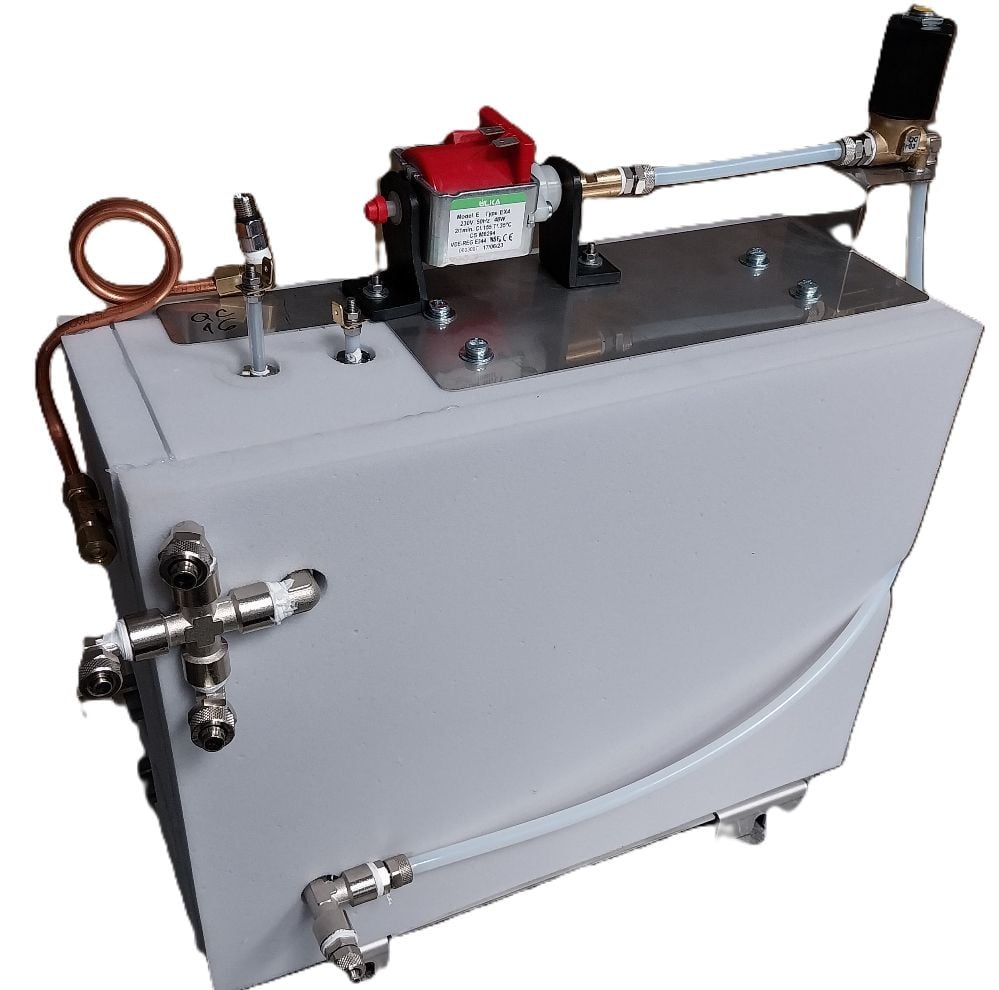

In Celitron Medical Technologies' latest sterilization equipment, a key component—the built-in steam generator—produces the high-pressure steam necessary for sterilization. This "mini boiler" fundamentally determines not only the efficiency but also the reliability of the devices, enabling quick and safe sterilization cycles. The essence of the steam generator is that it boils water in a closed container using electric heating elements, creating saturated, pressurized steam, which is then directed into the sterilization chamber. For example, Azteca AC series autoclaves use saturated steam as the sterilizing medium at temperatures up to 137 °C and pressures of 2.3 bar to eliminate all microorganisms on the surfaces of instruments to be sterilized.

High-temperature, pressurized steam is one of the most effective sterilization methods. This is because hot steam transfers immense thermal energy to objects, destroying bacteria, viruses, and spores within a few minutes of exposure. Modern autoclaves—such as Celitron's AC series devices—remove air from the chamber at the start of sterilization using a vacuum system. This allows steam at 121–134 °C to reach every cavity and surface, even inside packaged or porous materials. Thanks to vacuum pre-treatment and saturated steam, even heat-resistant pathogens are destroyed, making steam sterilization rightly considered the gold standard for disinfecting medical instruments.

The Azteca AC medium-capacity sterilizer range from Celitron integrates several innovations aimed at improving efficiency. Each model features a built-in steam generator, removing the need for an external steam supply — ensuring constant steam quality and fast cycles.

Additionally: vacuum pumps before and after the cycle assist in air removal and instrument drying. An automatic locking mechanism ensures safety.

Separate tanks handle clean and used water.

Precise sensors monitor temperature and pressure throughout the entire process.

The processes are managed by an advanced microprocessor controller that fully automates all operations.

The user can monitor the cycle in real time via a touchscreen, and the device includes self-diagnostic and computer connectivity functions.

Durability and ease of maintenance were also key considerations in designing these sterilizers. The main parts of the chamber and steam generator are made of corrosion-resistant, high-quality stainless steel, withstanding the stresses caused by high-pressure steam. The thoughtful design of internal and external components—including easily accessible modules, optimal insulation, and a streamlined piping system—facilitates maintenance tasks. The built-in self-diagnostic system continuously monitors the device's condition, further contributing to long service life and reliable operation. Moreover, Celitron's sterilizers employ water- and energy-saving modes: a special system minimizes water consumption during cycles, resulting in more economical operation and reduced environmental impact. This means users encounter fewer malfunctions, and maintenance intervals are extended, ensuring long-term, uninterrupted operation of the equipment.

It's no coincidence that Celitron's technology is considered a reliable choice in both healthcare and the biotechnology industry. The Azteca AC sterilizer family is used in over 40 countries worldwide and is recommended by numerous doctors and professionals. These devices meet the strictest international quality and safety standards (e.g., EN 285 European sterilizer standard, medical CE marking, ISO 13485 quality management). Thanks to stable performance, documented sterilization cycles, and high-level safety features, Celitron's AC series steam sterilizers offer an ideal solution for hospitals to sterilize surgical instruments, as well as for specialized sterilization tasks in biotechnology laboratories or pharmaceutical factories. The devices manufactured in Vác contribute to achieving the highest level of disinfection in healthcare, quickly and efficiently, ensuring maximum safety for patients and staff.

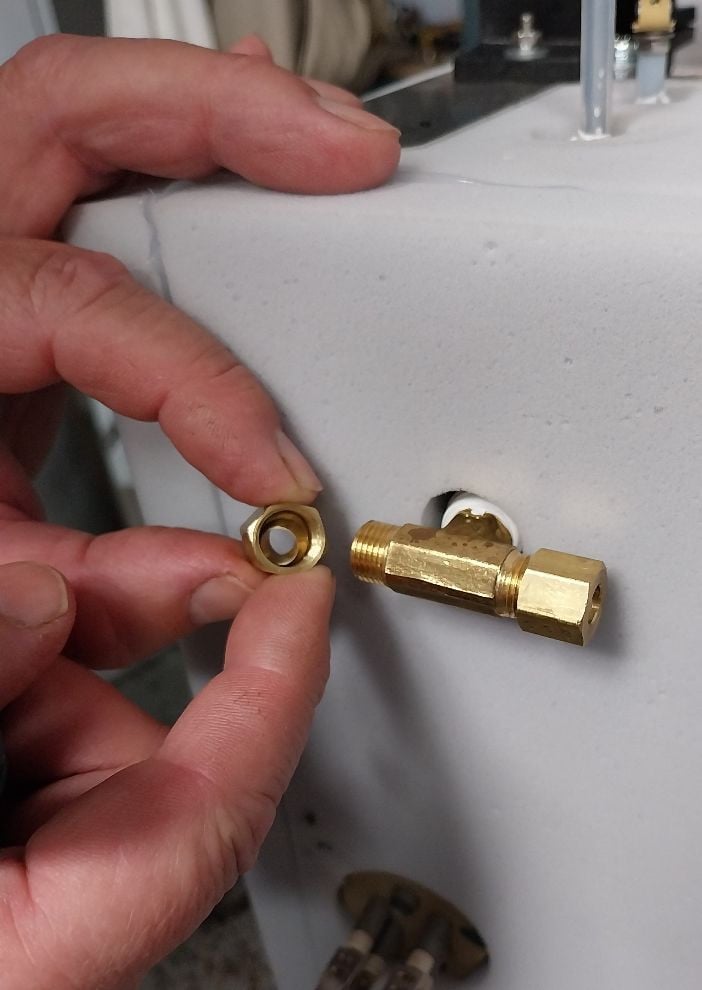

At Celitron, each steam generator is assembled by hand with the utmost expertise and attention, strictly adhering to industrial standards and quality assurance requirements. Every step of the precision assembly process is performed by experienced professionals—from preparing components to installing heating elements and sensors, to final insulation. Each generator undergoes rigorous testing procedures before being integrated into the sterilization equipment. Readers now have a rare glimpse into this process: the following photos reveal genuine "workshop secrets," showcasing how a reliable, long-lasting Celitron steam generator is born.