Black soldier fly larvae, cockroach, cricket, and other insects' protein powder extraction

Insect Protein Processing with ISS AGRI Facility

Recovery of Protein and Oil from Black soldier fly larvae/cricket/mealworm/cockroach or other edible insects

Our System, the ISS AGRI Facility provides a new process to recover protein and oil from Black soldier fly larvae and all type of insect, maggot.

Our facility is perfect solution for BSF farm, cricket farm, insect farm, maggot farm, black soldier larvae farm, grasshopper farm, fly farm, bug farm and cockroach farm as well. The Celitron ISS AGRI Facility can extract very high-quality protein from all type of insect. The ISS AGRI Facility is a new, unique agriprotein technology, with continuous and automated process system. All this is done with absolutely zero harmful emissions to the environment, and no bad odors whatsoever, so you won’t even have to worry about your own comfort while using it! What’s more, we’re not even the only ones recommending this solution for insect protein processing: the ISS AGRI Facility is also conform with all EU and WHO recommendations in the subject! In a nutshell, with its ease of use, eco-friendly operation, and undisputed efficiency, there is no doubt that this is one of the best pieces of equipment you can get for insect protein (e.g. cricket protein, cockroach protein) extraction!

Why Celitron ISS Agri Facility?

ISS AGRI Facility, the perfect rendering system for insect farming.

- Our system uses patented medical sterilization and shredding technology to prevent any possible contamination risk

- local and immediate treatment of the insect

- no transportation

- scalable system from 1-100 tonne / day capacity

- the system can be installed in a very limited space

- small footprint

- no production of organic, solid wastes

- low operating costs and fast return on investment

- no need for storage and transportation of raw materials

- minimal manpower needed for control and operation of the line.

- Very high-quality protein and oil due to mild production process

- the end-product is completely sterilized

- high productivity, better quantity of output.

This natural, sustainable, and performant source of proteins and oil is the perfect base for animal feed, pet feed and aquafeed.

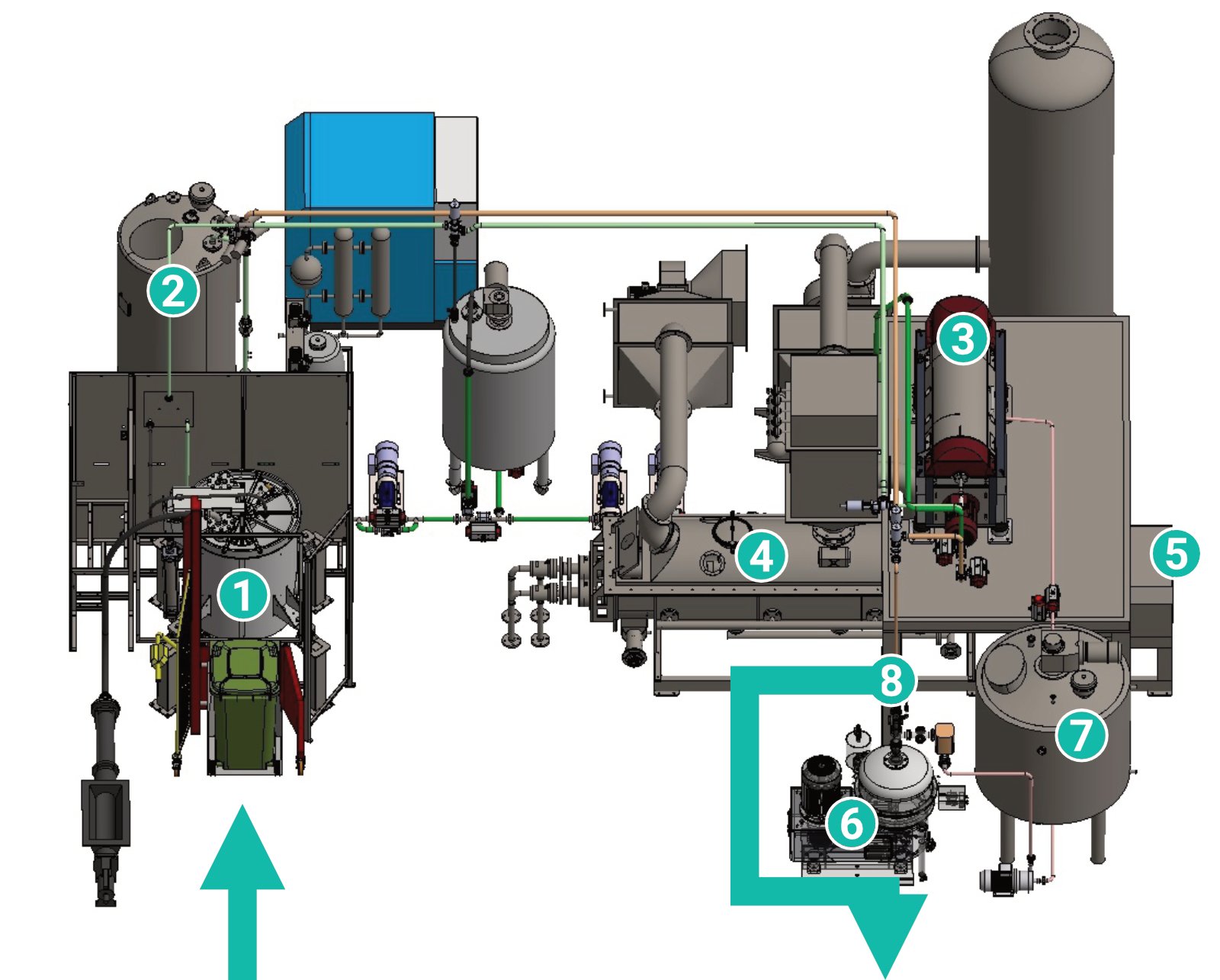

BSF (cricket, insect, maggot, bug…) rendering process with ISS Agri Facility for insect farming

- Insect larvae are cut and sterilized in the same pressure vessel, then the outcome is a ‘sterilized homogenous soup’.

- This soup is collected in the Buffer.

- Then goes to the Decanter, it separates this to solid and oil with water.

- The solids go to the Dryer to reduce the moisture level to 5-10%.

- The solid end-product is cooled down and collected into the dust.

- The oil with water is transferred to the Separator to improve the quality of the oil.

- The oil end-product has a 97.5% oil content.

- There is also a water end-product, that goes to the sewerage system.

The ISS AGRI Facility ensures an operation that is both user and environmentally friendly. First of all the insects will be loaded into the integrated sterilizer and shredder. After inputting the basic commands, the door of the vessel will close, and all you have to do is collect the separated and dried end-products that is perfect insect protein powder or cricket protein powder. Our cutting-edge sterilization technology is combined with extremely powerful shredding blades, so there is absolutely no risk of cross-contamination: anything that comes out of our processing facility is completely sterile BSF protein, cricket protein or other insect protein.

OPEN THE INSECT PROTEIN PROCESSING BROCHURE

You can find more details about our Insect Protein Processing.

Download nowINSECT FARMING AND LARVAE PROTEIN EXTRACTION AS A GLOBAL SOLUTION?

Another popular trend among today’s consumers isn’t just being health-conscious: people are also becoming more and more environmentally-conscious about where their food comes from, and under what conditions it is raised and processed. By using the ISS AGRI Facility, you will also be able to tend to the needs of those who are looking for more eco-friendly sources of protein.

With insect farming (black soldier fly farming), the health and environmental benefits are linked together. Edible insects like black soldier fly larvae, cricket, cockroach or grasshopper just don’t consume as much resources as other animals do. They need a lot less water and land for the protein extraction process to be completed, which is already a huge contribution to lessen the environmental burden on our world.

Trying to eat more healthily, and being more conscious about nutritional intake isn’t even a new trend, and edible insects fit right in. People looking for organic protein sources, or even athletes are more than likely potential customers.

What’s more, humans aren’t the only factors in this equation. Edible insects are also finding their way to the pet food or fish food market as a great protein source, making animal owners another segment that can be targeted if you have the tools to produce insect protein based foods. Even more reason to go for Celitron’s ISS AGRI Facility!

These benefits can also be felt by those who choose to invest in insect farming, since they are also more economically viable to grow. Since they need a lot less feed to produce the same (or an even greater) portion of edible meat, this means you’re spending less for their upkeep, and can sell more edible products!